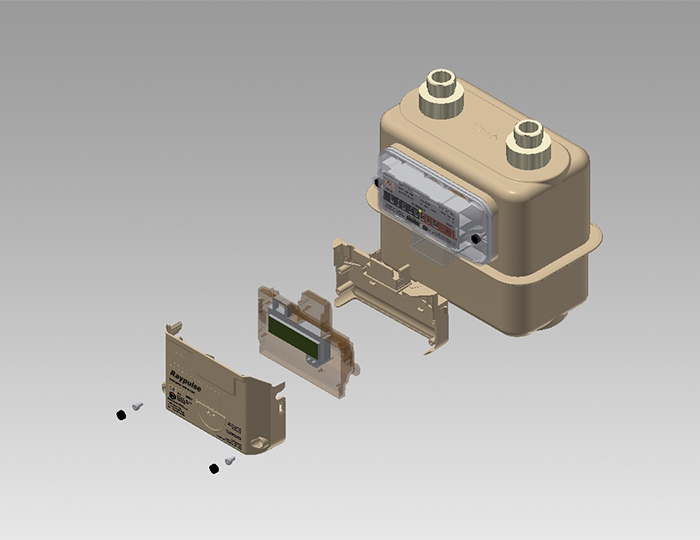

Transformer Services

We believe in offering solutions rather than selling products and have an in-house Services Team providing end-to-end solutions to our customers...

Discover Transformer Services

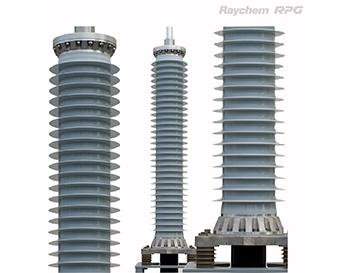

Power Services

Backed by decades of experience in the industry, Raychem RPG provides end-to-end customized solutions for reliable connection...

Discover Power Services