Your Design!

Our Solution!

No Search Result

Your Design!

Our Solution!

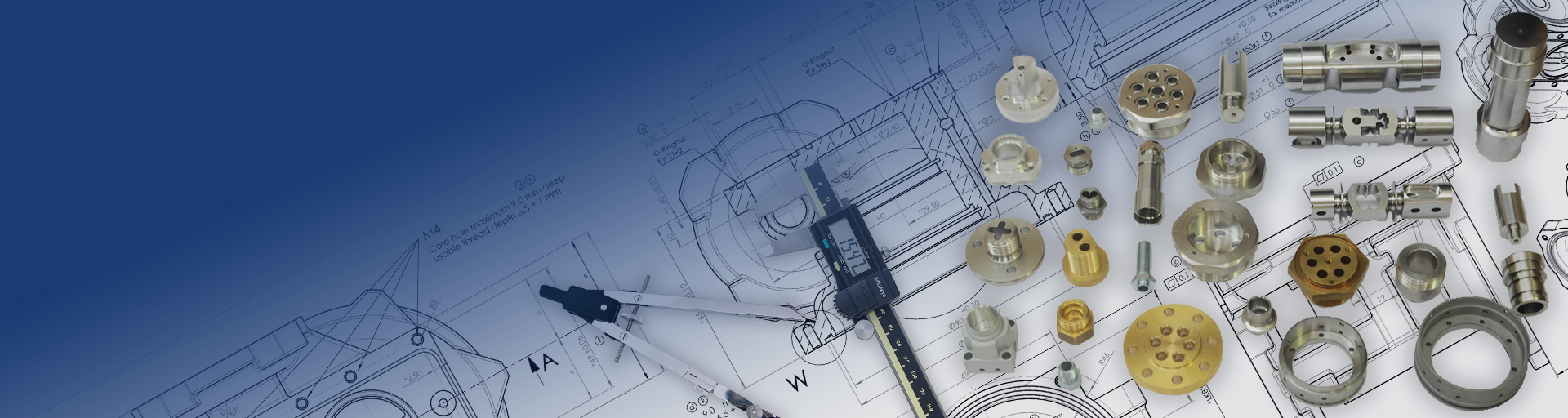

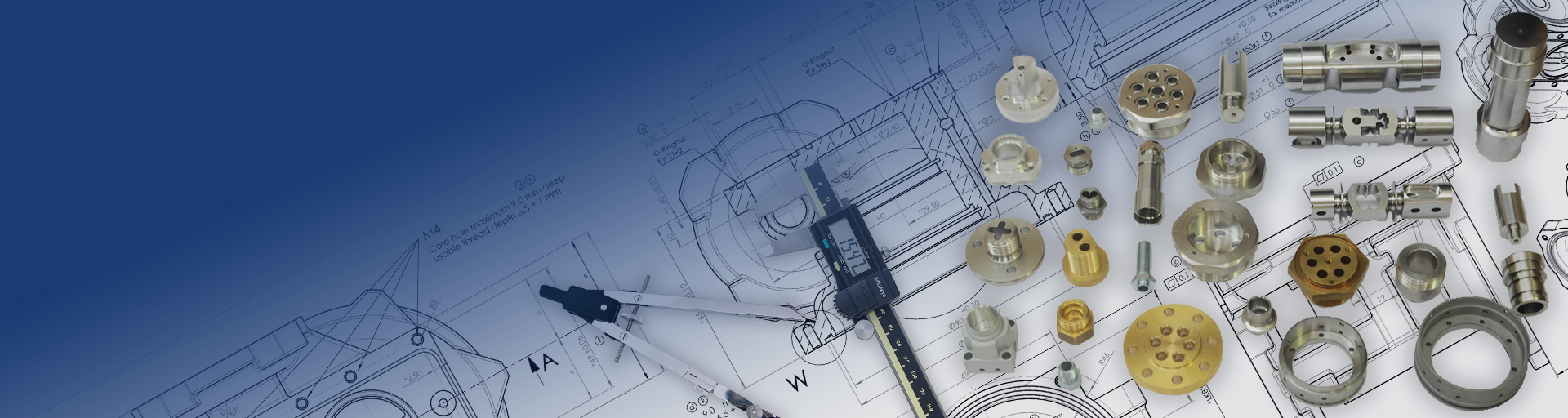

Build-to-print is what we call the building of Customized components & Products to exact specifications & designs required for any product. These specifications come in the form of design inputs that are proprietary to our customers. Build-to-print designs are typically specified down to the dimensions, materials & other specific surface treatments & testing.

With diversified technology and processes, Raychem RPG manufactures a wide range of high precision metal, plastic and rubber components as per customers' design including machining, casting, forging & stamping, and others secondary processes like heat and surface treatments.

Whether you require a proto, pilot or production volumes, partner with Raychem RPG for your next contract manufacturing project.

High quality die-cast, sand cast and investment casted, defect free products

Learn More

High Quality sheet metal and welded components

Learn More

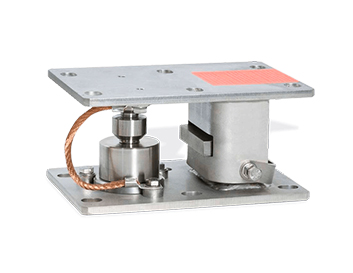

Precision & close tolerance components, machined from forged/bar route

Learn More

Customized rubber to metal bonded parts as per our client specific needs

Learn More

Migration Project from Europe to India helps one of our client to smoothen out their Supply Chain by reducing the dependency on various suppliers and integrating them with Raychem RPG alone which helped in reducing the overall lead time in delivering the products to Market and improving the overall efficiency & minimise multi dependency risk

Learn More Vipul Tikekar

Vipul Tikekar vipul_Tikekar@raychemrpg.com

vipul_Tikekar@raychemrpg.com 9881146941

9881146941