No Search Result

Connect with us by clicking on one of the following options.

Sales Enquiry Visit Contact Page

Sales Enquiry Visit Contact Page Grievance Officer grievance_officer@raychemrpg.com

Grievance Officer grievance_officer@raychemrpg.com Other Enquiry info@raychemrpg.com

Other Enquiry info@raychemrpg.com Chat with Us Mon. to Sat. 9am to 6pm

Chat with Us Mon. to Sat. 9am to 6pm

-

-

Your List Is Empty

- View Products

- Features

- Help & Support

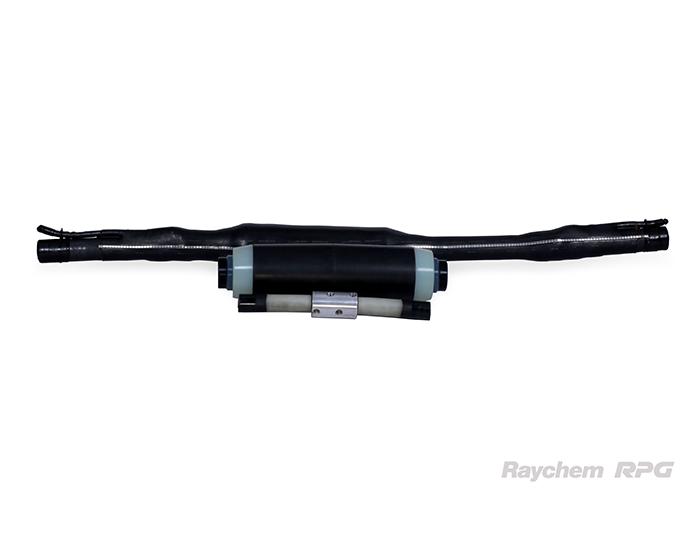

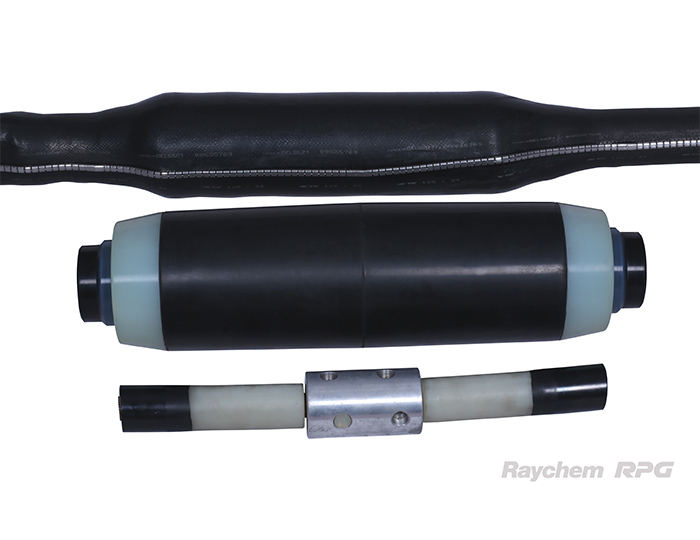

Pre moulded design of Joints for voltages upto 245 kV. Available in Single/One piece design upto 245 kV and Three piece design for 145 kV. The silicone rubber joint body with integrated geometrical stress control, provides proven electrical functions. Joint components combine electrical performance, stress control and moisture sealing to provide important functions required for high voltage equipment.

Single Piece - Premoulded one-piece joint body upto 245 kV

- Torque-controlled connector

- Joint fits on all polymeric cable constructions

- Proven shield continuity concept

- Factory tested silicone rubber body

- Special silicone rubber provides perfect compression force for optimized electrical performance

- Simple assembly

- Choice of outer sealing and protection system

- No tension set of joint body

- Moulded/Painted outer conductive screen

- Geometrical electrical stress control by moulded conductive deflectors

- Type tested according to IEC 60840, IEC 62067 standards

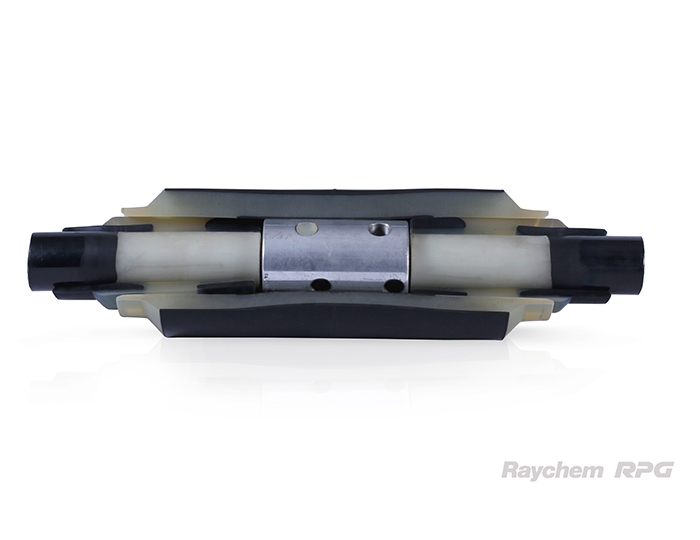

Three Piece - Premoulded three-piece joint design upto 145 kV

- Torque-controlled connector

- Joint fits on all polymeric cable constructions

- Proven shield continuity concept

- Factory tested silicone rubber body

- Special silicone rubber provides perfect compression force for optimized electrical performance

- Short cut-back dimensions, cable size transition possible

- No special tools required for installation

- No tension set of joint body

- Moulded outer conductive screen

- Geometrical electrical stress control by moulded conductive deflectors

- Type Tested as per IEC: 60840

- more...

- Catalog

- Add to List

- Enquire Now

Please connect with us

Chat with Us Mon. to Sat. 9am to 6pm

Chat with Us Mon. to Sat. 9am to 6pm

Specifications

|

Single Piece Joint 72/145 kV/245 kV |

|||

|---|---|---|---|

|

Rated kV |

36/66 (72) |

76/132 (145) |

127/220 (245) |

|

Diameter over insulation |

37.86 - 75.20 mm |

37.86-96.80 mm |

60.70-128.25 mm |

|

Diameter over sheath |

≤ 120 mm |

≤ 140 mm |

≤ 160 mm |

|

Cable screen types |

Cu-wires w/o laminated foil, lead sheath, corrugated metal sheath, Cu-tape (other types and combinations on request) |

Cu-wires w/o laminated foil, lead sheath, corrugated metal sheath, Cu-tape (other types and combinations on request) |

Corrugated aluminium sheath/Lead sheath/Cu wire. etc. |

|

Max. Cross section (Cu / Al) |

≤ 1200 mm² |

Approx. 1600 mm² |

≤ 2500 mm² |

|

Conductor connection |

Mechanical (shear head bolts) |

Mechanical (shear head bolts) |

Mechanical (shear head bolts) |

|

Material of connection bolt |

Aluminum / Copper |

Aluminum / Copper |

Aluminum / Copper |

|

Max. permissible dielectric stress |

4 kV/mm (at insulation screen of cable) |

4 kV/mm (at insulation screen of cable) |

4 kV/mm (at insulation screen of cable) |

|

Outer protection |

Reinforced composite laminate wrap around with an integral moisture barrier/Copper Casing/FRP box with PU compound |

Reinforced composite laminate wrap around with an integral moisture barrier/Copper Casing/FRP box with PU compound |

Reinforced composite laminate wrap around with an integral moisture barrier/Copper Casing/FRP box with PU compound |

|

Method of stress control |

Geometric |

Geometric |

Geometric |

|

Material main body |

Silicone rubber |

Silicone rubber |

Silicone rubber |

|

Installation temperature |

0 °C - +40 °C |

0 °C - +40 °C |

0 °C - +40 °C |

|

Operation temperature |

-55 °C - +50 °C |

-55 °C - +50 °C |

-55 °C - +50 °C |

|

Storage temperature |

0 °C - +40 °C |

0 °C - +40 °C |

0 °C - +40 °C |

|

Three-Piece 145 kV Joint |

|

|---|---|

|

Diameter over insulation |

43 – 84 mm |

|

Diameter over sheath |

105 mm |

|

Cable screen types |

Cu-wires w/o laminated foil, lead sheath, corrugated metal sheath, Cu-tape (other types and combinations on request) |

|

Max. Cross section (Cu / Al) |

Approx. 3000 mm² |

|

Conductor connection |

Mechanical (shear head bolts) |

|

Material of connection bolt |

Aluminium / copper |

|

Max. permissible dielectric stress |

4 kV/mm (at insulation screen of cable) |

|

Outer protection |

Reinforced composite laminate wrap around with an integral moisture barrier/Copper Casing/FRP box with PU compound |

|

Method of stress control |

Geometric |

|

Material main body |

Silicone rubber |

|

Installation temperature |

0 °C - +40 °C |

|

Operation temperature |

-55 °C - +50 °C |

|

Storage temperature |

0 °C - +40 °C |

Technical Information

|

Single Piece Joint 72/145 kV/245 kV |

||||

|---|---|---|---|---|

|

Relevant standard |

|

IEC 60840 |

IEC 60840 |

IEC 62067 |

|

Rated voltage U0/U (Um) |

kV |

36/66 (72) |

76/132 (145) |

127/220 (245) |

|

Rated frequency |

Hz |

50 |

50 |

50 |

|

Lightening impulse voltage 1,2/50μs |

kV |

350 |

650 |

1050 |

|

AC Voltage withstand test (15/30 min) |

kV |

90 |

190 |

254/318 |

|

Partial discharge 1.5 Uo kV |

pC |

≤5 |

≤5 |

≤5 |

|

Rated current |

A |

as per cable |

as per cable |

as per cable |

|

Rated short-circuit current (conductor) 1s |

kA |

as per cable |

as per cable |

as per cable |

|

Rated short circuit current (sheath) 1s |

kA |

As per cable |

As per cable |

As per cable |

|

DC Voltage test between metallic sheath/screen and earthed exterior |

kV |

25 |

25 |

25 |

|

Three-Piece 145 kV Joint |

||

|---|---|---|

|

Relevant standard |

|

IEC 60840 |

|

Rated Voltage Uo/U (Um) |

kV |

76/132 (145) |

|

Rated frequency |

Hz |

50 |

|

Lightening impulse voltage 1,2/50µs |

kV |

650 |

|

AC Voltage withstand test (30 min) |

kV |

190 |

|

DC Voltage withstand (15 min) |

kV |

315 |

|

Rated current |

kA |

as per cable |

|

Rated short-circuit current (conductor) |

kA |

as per cable |

|

Rated short-circuit current (sheath) 1s |

kA |

50 |

|

DC Voltage test between metallic sheath/screen and earthed exterior |

kV |

25 |

Certifications

CPRI

More info available on request

KEMA

More info available on request

KIT

More info available on request

Related Products

All products provided below with slider to find faster.

Share

Share