No Search Result

Connect with us by clicking on one of the following options.

Sales Enquiry Visit Contact Page

Sales Enquiry Visit Contact Page Grievance Officer grievance_officer@raychemrpg.com

Grievance Officer grievance_officer@raychemrpg.com Other Enquiry info@raychemrpg.com

Other Enquiry info@raychemrpg.com Chat with Us Mon. to Sat. 9am to 6pm

Chat with Us Mon. to Sat. 9am to 6pm

-

-

Your List Is Empty

- View Products

- Features

- Help & Support

Heat-shrinkable busbar insulation tubing. Busbar heat-shrinkable tubing are suitable for use on long runs of rectangular or round busbars. The tubing shrinks down to 40% of their original diameter and, due to excellent flexibility, conform tightly to a wide range of sizes. BBIT/BPTM tubing can be slid easily into place, even around several bends and awkward shapes. The wall thickness is controlled by heat-shrink process. Available for over fifteen sizes of busbars from 5 mm to over 250 mm, BPTM/RBPM is suitable for applications up to 24 kV. BBIT is suitable for applications up to and over 36 kV.

- Insulation enhancement and protection against flashover and accidentally induced discharge

- Excellent flexibility enables installation on wide range of curved or bent busbars without cracking or creasing

- Exceptional insulation and long-term reliability even at high continuous operating temperatures

- Non-Halogen based material

- Catalog

- Add to List

- Enquire Now

Please connect with us

Email Us epd@raychemrpg.com

Email Us epd@raychemrpg.com Chat with Us Mon. to Sat. 9am to 6pm

Chat with Us Mon. to Sat. 9am to 6pm

Specifications

BBIT

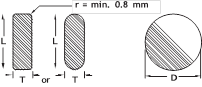

BBIT should normally be used on the following busbar sizes

Product selection

| Product size | Rectangular bars L + T (mm) | Round bars D (mm) | ||

|---|---|---|---|---|

| min. | max. | min. | max. | |

| BBIT 25/10 | 17 | 28 | 11 | 20 |

| BBIT 40/16 | 28 | 45 | 18 | 32 |

| BBIT 65/25 | 44 | 69 | 28 | 47 |

| BBIT 100/40 | 6 | 102 | 44 | 72 |

| BBIT 150/60 | 102 | 148 | 65 | 105 |

| BBIT 175/80 | 133 | 196 | 85 | 125 |

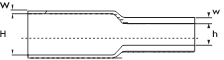

Ordering information

| Ordering description | Inside diameter (mm) | Wall thickness (mm) | UOM: roll | |||

|---|---|---|---|---|---|---|

| H min. |

h max. |

W nom. |

w min. |

length (m) |

||

| BBIT-25/10-A/U-4 25 | 10 | 1.6 | 3.6 | 25 | ||

| BBIT-40/16-A/U-4 40 | 16 | 1.6 | 3.6 | 20 | ||

| BBIT-65/25-A/U-4 65 | 25 | 1.6 | 3.6 | 15 | ||

| BBIT-100/40-A/U-4 | 100 | 40 | 1.6 | 3.6 | 15 | |

| BBIT-150/60-A/U-4 | 150 | 60 | 1.6 | 3.6 | 15 | |

| BBIT-175/80-A/U-4 | 175 | 80 | 1.6 | 3.6 | 10 | |

BPTM / RBPM

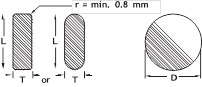

BPTM should normally be used on the following busbar sizes

Product selection

| Product size | Rectangular bars L + T (mm) | Round bars D (mm) | ||

|---|---|---|---|---|

| min. | max. | min. | max. | |

| BPTM 15/6 | 12 | 18 | 6.5 | 12 |

| BPTM 30/12 | 22 | 38 | 13.5 | 25 |

| BPTM 50/20 | 36 | 65 | 22 | 43 |

| BPTM 75/30 | 55 | 95 | 33 | 63 |

| BPTM 100/40 | 70 | 130 | 44 | 86 |

| BPTM 120/50 | 90 | 165 | 55 | 105 |

| BPTM 175/70 | 125 | 235 | 80 | 150 |

| BPTM 205/110 | 200 | 276 | 127 | 190 |

| BPTM 235/130 | 235 | 315 | 150 | 220 |

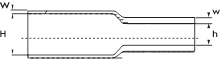

Ordering information

| Ordering description | Inside diameter (mm) | Wall thickness (mm) | UOM: roll | |||

|---|---|---|---|---|---|---|

| H min. |

h max. |

W nom. |

w min. |

length (m) |

||

| BPTM-15/6-A/U-4 | 15 | 6 | 1.1 | 1.90 | 30 | |

| BPTM-30/12-A/U-4 | 30 | 12 | 1.1 | 2.20 | 30 | |

| BPTM-50/20-A/U-4 | 50 | 20 | 1.1 | 2.35 | 30 | |

| BPTM-75/30-A/U-4 | 75 | 30 | 1.1 | 2.35 | 20 | |

| BPTM-100/40-A/U-4 | 100 | 40 | 1.1 | 2.35 | 25 | |

| BPTM-120/50-A/U-4 | 120 | 50 | 1.3 | 2.80 | 25 | |

| BPTM-175/70-A/U-4 | 175 | 70 | 1.3 | 2.80 | 15 | |

| BPTM-205/110-A/U-4 | 205 | 110 | 1.3 | 2.80 | 10 | |

| BPTM-235/130-A/U-4 | 235 | 130 | 1.5 | 3.10 | 20 | |

Technical Information

|

Key product specifications |

Test method |

Requirement |

|---|---|---|

|

Thermal endurance |

IEC 216 |

105 °C min. |

|

Accelerated ageing

|

ISO 188, ASTM D2671 |

168 hrs @ 120 °C 10 MPa min. 300% min. |

|

Comparative tracking index |

IEC 112, VDE 0303/1 |

KA 3c |

|

Dielectric strength |

ASTM D149, IEC 243 |

180 kV/cm min. @ 2 mm 150 kV/cm min. @ 2.5 mm 120 kV/cm min. @ 3 mm |

|

Smoke index |

NES 711 |

Less than 120 |

|

Acid gas generation |

Raychem PPS 3010 4.23 |

Less than 1% by weight |

|

Low temperature flexibility |

ASTM D2671 Procedure C |

No cracking after 4 hrs @ -40 °C |

|

Flammability |

ANSI C37.20/IEEE-27 |

No flame conveyance, 60 sec. max. |

|

Tracking and Erosion Resistance |

ASTM D2303 |

No tracking, erosion to top surface or flame failure after 1 hr. at 2.5kV, after 1 hr. at 2.75kV, 1% max. |

Certifications

CPRI

More info available on request

ERDA

More info available on request

Related Products

All products provided below with slider to find faster.

Share

Share