No Search Result

Connect with us by clicking on one of the following options.

Sales Enquiry Visit Contact Page

Sales Enquiry Visit Contact Page Grievance Officer grievance_officer@raychemrpg.com

Grievance Officer grievance_officer@raychemrpg.com Other Enquiry info@raychemrpg.com

Other Enquiry info@raychemrpg.com Chat with Us Mon. to Sat. 9am to 6pm

Chat with Us Mon. to Sat. 9am to 6pm

-

-

Your List Is Empty

- View Products

- Features

- Help & Support

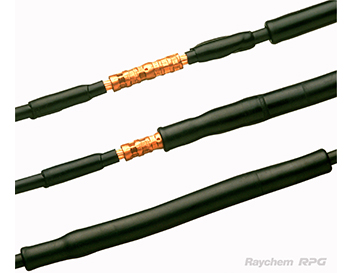

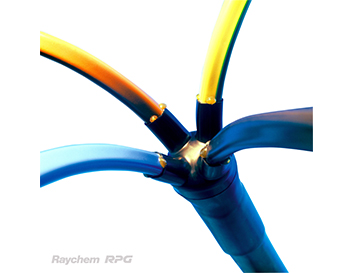

Medium Voltage Heat Shrink Joints-Conventional and next generation. Raychem developed highly specialized polymers for heat shrink joints suitable for plastic and paper cables upto 36 kV. For transition joints, a special oil barrier tubing is used to transform draining oil (MI) and non-draining oil (MIND) paper insulated cable into quasi-polymeric insulated cable with a radial field.

The conventional design developed in 1980 was based on multiple layer tubing concept providing insulation and stress functions. The latest developed heat shrink joint is a single tubing (triple layer co-extruded) of adequate thickness which provides insulation for a particular voltage range.

- Conventional Joints - Multi-layered heat-shrinkable tubing incorporating precisely engineered impedance stress control. EPKJ universal joints are suitable for a wide range of connectors and cable sizes with no limitations on shelf life

- Joints are suitable for all types of cables having different screening and armour designs

- Immediate energization after completion of joints

- Conforms to various national and international standards like CENELEC HD.629.1.S2:2006, IEC 60502-4, IEEE 48 and IS 13573-2

- Next Gen Joints - Triple layer co-extruded single heat-shrinkable tubing incorporating precisely engineered impedance stress control. MXSU joints are supplied with mechanical phase and screen connectors for a wide range of conductor sizes with no limitat

- Joints are suitable for all types of cables having different screening and armour designs

- Immediate energization after completion of joints

- Conforms to various national and international standards like CENELEC HD.629.1.S2:2006, IEC 60502-4, IEEE 48 and IS 13573-2

- more...

- Catalog

- Add to List

- Enquire Now

Please connect with us

Chat with Us Mon. to Sat. 9am to 6pm

Chat with Us Mon. to Sat. 9am to 6pm

Specifications

| Parameter |

|---|

| Unlimited shelf life for heat shrink components |

| Suitable for wide range of connectors |

| Immediate energization |

| Pre-Engineered Kit |

| Tested as per National & International Standards |

Technical Information

|

Sr. No. |

Particulars |

7.2 KV |

12 KV |

24 KV |

36 KV |

|---|---|---|---|---|---|

|

1. |

Applicable Standards |

IEC 60502-4, CENELEC HD 629.1, IS 13573-2 |

|||

|

2. |

Rated Voltage of cable accessories |

3.8/6.6 (7.2) |

6.35/11 (12) |

12.7/22 (24) |

19/33 (36) |

|

3. |

Brand |

Raychem-RPG |

Raychem-RPG |

Raychem-RPG |

Raychem- RPG |

|

4. |

Accessories |

Heat Shrink type |

|||

|

5. |

AC Voltage test Dry for 5 minutes Wet for 1 minute |

17.1 kV 15.2 kV |

28.5 kV 25.4 kV |

57.1 kV 50.8 kV |

85.5 kV 76 kV |

|

6. |

DC Voltage test for 15 min |

15.2 kV |

25.4 kV |

50.8 kV |

76 kV |

|

7. |

Partial Discharge at 1.73U0 |

Less than 10 pC |

|||

|

8. |

Impulse Voltage at ambient & elevated temp |

60 kVp |

75 kVp |

125 kVp |

170 kVp |

|

9. |

Load Cycle test |

60 cycles in air & water |

|||

|

a. |

Each cycle heating duration |

5 hours |

|||

|

b. |

Temperature |

95 - 100° C |

|||

|

c. |

Cooling Duration |

3 hours |

|||

|

d. |

Voltage withstand |

9.5 kV |

15.8 kV |

31.7 kV |

47.5 kV |

|

10. |

Humidity Test for 300 hrs. |

4.7 kV |

7.93 kV |

15.8 kV |

23.7 kV |

|

11. |

Salt fog test for 1000 hrs. |

4.7 kV |

7.93 kV |

15.8 kV |

23.7 kV |

|

12. |

Method of Stress Control |

Resistive based (ZnO based available in termination on req.) |

|||

|

13. |

Tubing & Molded parts |

Heat Shrinkable type |

|||

|

14. |

Non-tracking material |

As per ASTM D-2303 |

|||

|

15. |

Di-electric strength of insulating material |

10 kV/mm minimum |

|||

Certifications

CPRI

More info available on request

ERDA

More info available on request

Related Products

All products provided below with slider to find faster.

Share

Share