Customizable

Customizable

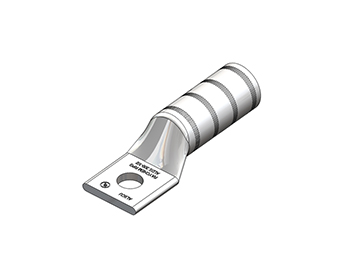

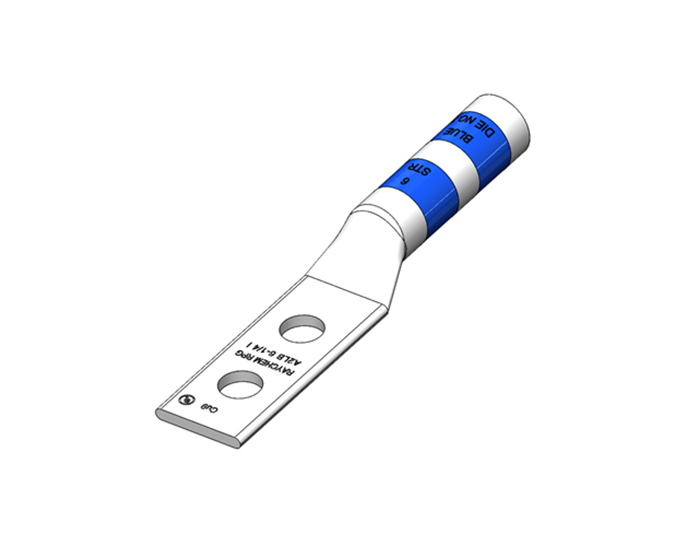

A2LDS - Two-hole Lugs - Aluminium Dual Rated

For aluminium and copper conductors

Learn More

Customizable

Customizable

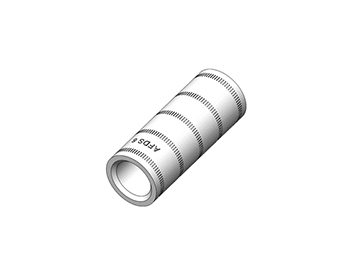

AFDS - Two-way Splice Connectors - Aluminium Dual Rated

Standard barrel with crimps for reliable connection

Learn More

Customizable

Customizable

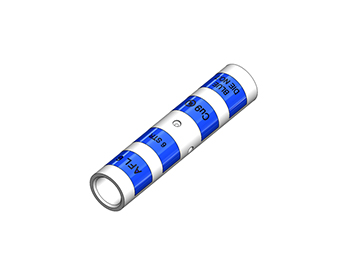

AFL - Two-way Splice Connectors - Long Barrel

Long barrel with multiple crimps for secured connection

Learn More

Customizable

Customizable

AFS - Two-way Splice Connectors - Standard Barrel

Standard barrel with crimps for reliable connection

Learn More

Customizable

Customizable

ALDH - One-hole Lugs - Aluminium Dual Rated Heavy Duty

For heavy duty aluminium and copper conductors

Learn More

Customizable

Customizable

ALDS - One-hole Lugs - Aluminium Dual Rated

For aluminium and copper conductors

Learn More

Customizable

Customizable

RADE - One-hole Lugs - Aluminium Lugs as per DIN 46329

For aluminium and copper conductors and best suited to avoid rotation or movement of lugs

Learn More

Customizable

Customizable

RCD - Two-way Splice Connectors - DIN 46267 Part-1

Splices designed as per DIN Standard 46267, Part-1

Learn More

Customizable

Customizable

RCL - Two-way Splice Connectors - Long Barrel

Long barrel with multiple crimps for secured connection

Learn More

Customizable

Customizable

RCRL - In line Connectors - Reducing Link

Application for different sizes of cable connections

Learn More

Customizable

Customizable

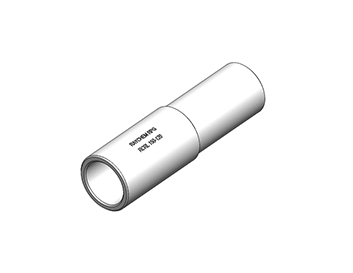

RCS - Two-way Splice Connectors - Short Barrel

Standard barrel with crimps for reliable connection

Learn More

Customizable

Customizable

RLAX - One-hole Lugs - Aluminium Lugs for XLPE Cables

For significant lower dead weight aluminium conductors in power distribution application

Learn More

Share

Share

Chat with Us

Chat with Us